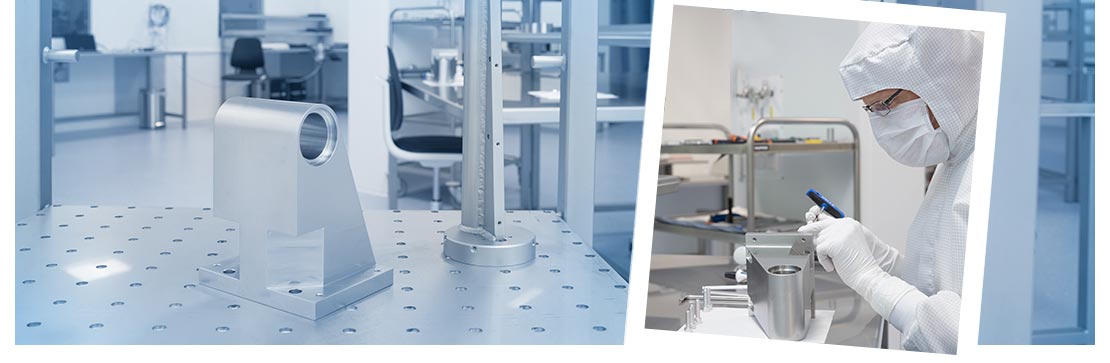

Cleanroom assembly

Ultra-clean assembly (UCA)

Reinraumtaugliche Bauteile durch anforderungsgerechte Vorreinigung

Having its own ISO 5 cleanroom enables ALMA to offer customers bespoke cleanroom assembly services, ranging from the assembly of UCV components to complete, tested assemblies.Workpieces weighing up to 1,000 kg can thus undergo UCA-compliant assembly to the highest standards of cleanness.

ALMA provides continuous training to ensure that its cleanroom personnel meet the latest UCA cleanness standards.

In order to maintain the achieved level of cleanness during transport and to protect the components and assemblies from fresh contamination, they are packaged under cleanroom conditions (ISO 5).

If products have to be further processed by the customer in a cleanroom, this is done by means of double packaging in an inert gas atmosphere of the highest purity, as this enables them to be reintroduced into the cleanroom without contamination.

The packaged products are labelled directly on the inner film with UCA-certified labels to customer specification.

If products have to be further processed by the customer in a cleanroom, this is done by means of double packaging in an inert gas atmosphere of the highest purity, as this enables them to be reintroduced into the cleanroom without contamination.

The packaged products are labelled directly on the inner film with UCA-certified labels to customer specification.

Cleanroom packaging services

- Sealing in certified PE bags or with composite films

- Use of inert N2 atmosphere of the highest purity

- Labelling to customer requirements with cleanroom-compatible materials

- Outer packaging of PE film