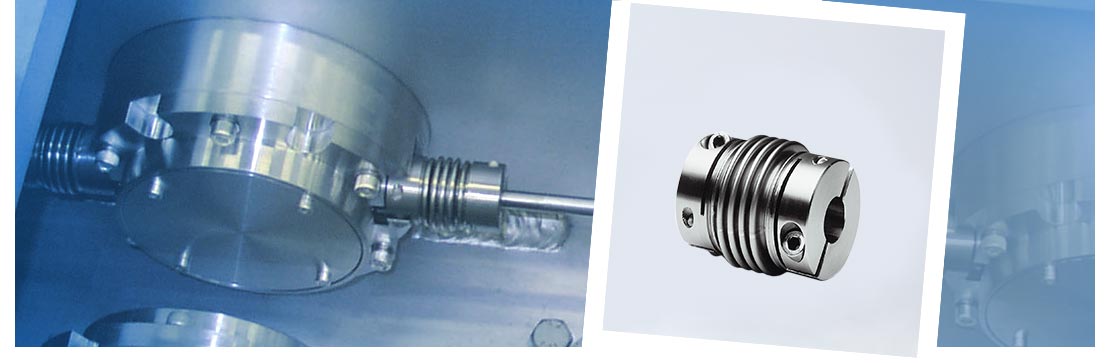

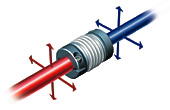

Principle Function of Metal Bellow Couplings

ALMA Metal Bellow couplings connect shafts absolutely torsion stiff. They balance misalignment in lateral, angular and axial direction.

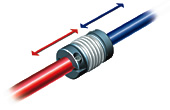

Balancing the angular offset of two shafts

Balancing the angular offset of two shafts

Balancing the angular offset of two shafts

Balancing the angular offset of two shaftsIn circumferential direction they operate like a rigid element, this way they can transfer drag torques absolutely torsion stiff.

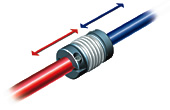

Balancing the parallel offset of two shafts

Balancing the parallel offset of two shafts

Balancing the parallel offset of two shafts

Balancing the parallel offset of two shaftsShaft misalignments can cause higher loads on the bearings. These misalignments can be minimized by using metal bellow couplings.

This will increase the product lifetime of the bearing.

Balancing the

length offset of two shafts

Balancing the

length offset of two shafts

Balancing the

length offset of two shafts

Balancing the

length offset of two shaftsMiniature Metal Bellow Couplings

The miniature couplings type AMK

and AMKN balance misalignments of rotating shafts and ensure an

absolute synchronized transfer of

rotating movements.

They feature a low angular momentum and high torsion stiffness. They are applicable for nominal torques of

0,25 Nm - 12 Nm for shaft diameters

of 1 mm - 24 mm.

Benefits at a Glance:

- Low angular momentum

- Balancing of misalignments

- Temperature range up to 80 °C

- Compact Design

- Free of wear and play

- Easy Mounting and Demounting

Torsion stiff Metal Bellow Couplings

ALMA Metal Bellow Couplings type

ATM feature a welded bonding.

This ensures higher temperature

resistance and higher mechanical

strength.

Clamping types are conical clamp

connections, radial or axial clamping hubs, etc.

ALMA Metal Bellow Couplings are applicable for nominal torques of

10 Nm - 320 Nm for shaft diameters

of 8 mm - 60 mm.

Benefits at a Glance:

- Low angular momentum

- High torsion stiffness

- Balancing of misalignments

- Temperature range up to 300 °C

- Variable clamping possibilities

- Torque transfer exact and free of play

- Easy Mounting and Demounting