High-performance cooling systems for rotary feedthroughs

Reliable cooling systems for every application

ALMA offers a comprehensive range of cooling systems for rotary feedthroughs. The product range includes simple cooling sleeves, housing and shaft cooling systems as well as combined solutions.The use of integrated ALMA cooling systems means that the customer does not need to design his own system or purchase a third-party system. This makes the cooling more reliable, economical and compact and also easier to assemble.

Depending on the type of thermal loading, ALMA uses a standard solution or develops a cooling concept tailored to the requirements for the specific application.

Please feel free to contact us!

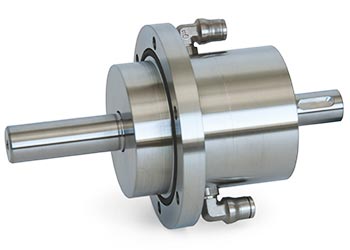

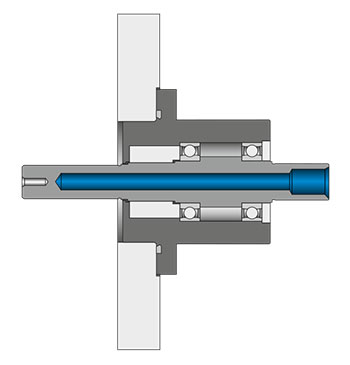

Rotary feedthrough with housing cooling

Thermal loading through the recipient wall

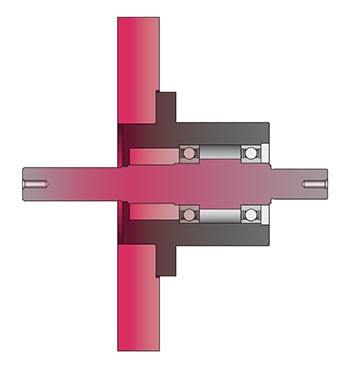

Temperature reduction using a cooling sleeve

If the heat loading via the recipient wall is moderate, a low-cost cooling sleeve is used, which is hermetically separated from the sealing medium.

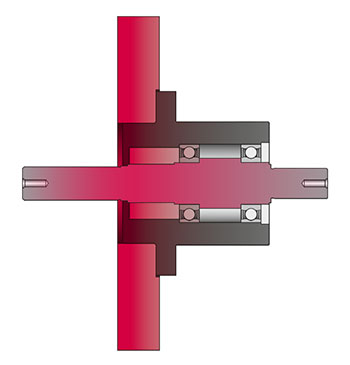

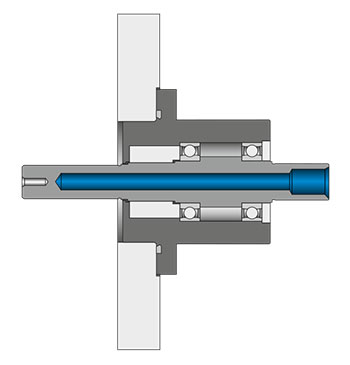

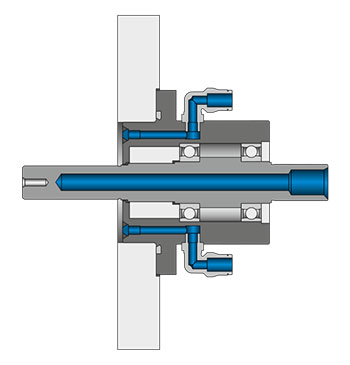

High thermal loading through the recipient wall

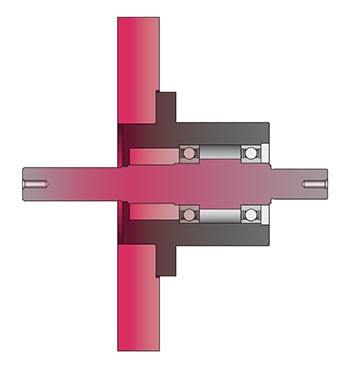

Temperature reduction by cooling the housing

If the heat loading via the recipient wall is higher, a cooling passage, which is hermetically separated from the sealing medium, is integrated into the housing, enabling a higher cooling capacity.

The design concept of ALMA cooling systems

As a general rule, in ALMA cooling systems no cooling medium is in direct contact with the sealing medium. It is always hermetically separated from static O-rings and the fluid seal. This prevents water penetrating the vacuum in the event of an O-ring failure.

Because the fluid seal should not be subjected to temperatures above 90 °C, we design the cooling accordingly. The fluid itself can withstand higher temperatures, but experienced engineers know that at temperatures above 90 °C thermal expansion can occur in the other materials employed, resulting in leakage if the cooling is insufficient.

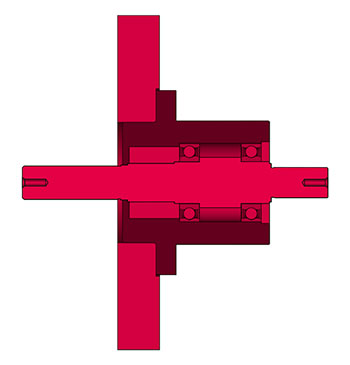

High thermal loading

via the shaft

via the shaft

Temperature reduction by cooling the shaft

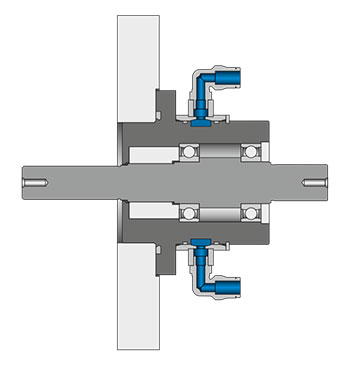

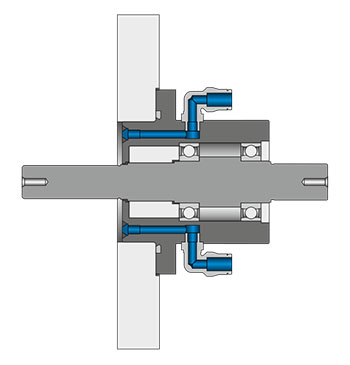

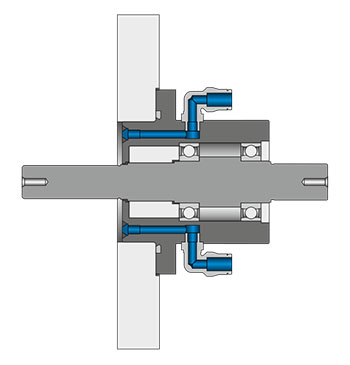

In the case of high thermal loading via the shaft end on the vacuum side, the shaft itself is cooled. For this purpose our standard product range includes a rotational water input connection.

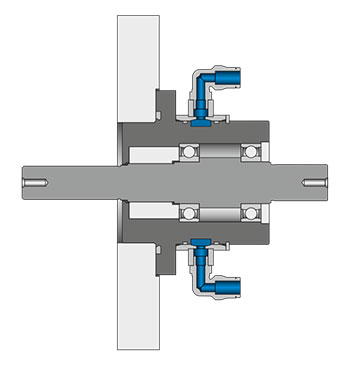

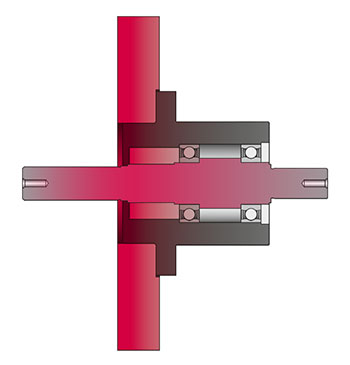

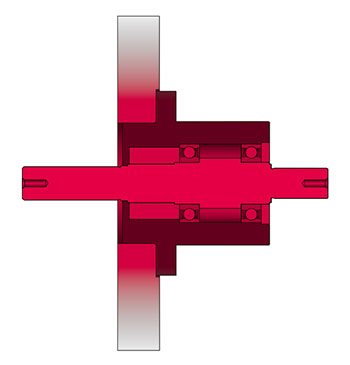

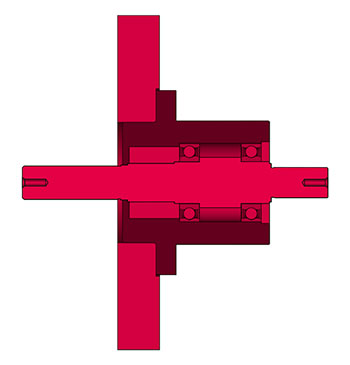

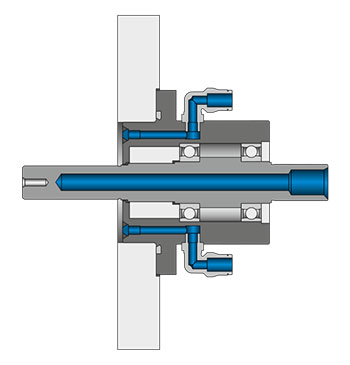

Very high thermal loading via the recipient wall and the shaft

Temperature reduction by cooling the housing and shaft

If the thermal loading is very high, the cooling concepts can be combined to achieve maximum cooling efficiency.

Rotary feedthrough with shaft cooling