ALMA sealing technology ensures the highest level of purity in the vacuum

The reliable sealing concept: magnetic fluid seals

The design focus of the ALMA rotary feedthroughs is on tightness and a high level of operational reliability. Our wear-free sealing concept based on magnetic fluid prevents mechanical abrasion, guaranteeing not only a long service life but also a high level of purity in the vacuum application. This benefits the customer, as maintenance downtime is no longer necessary, ensuring maximum system availability.Magnetic fluid seals utilize the reaction of magnetic fluids to an applied magnetic field. In principle, the seal consists of two pole pieces, a magnet, the magnetic fluid, a rotating shaft and a housing. The magnetic fluid is held in place annularly by the magnetic field at the sealing position between the pole pieces and the rotating shaft. The magnetic fluid thus creates a "liquid sealing lip" and seals hermetically.

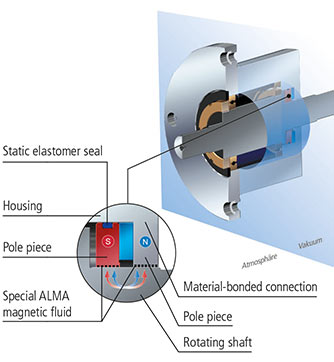

In standard products, the static seal between the housing and the pole pieces is produced by an elastomer O-ring.

The magnetic fluid sealing technology for a high level of vacuum reliability

High-quality special magnetic fluid for maintenance-free applications

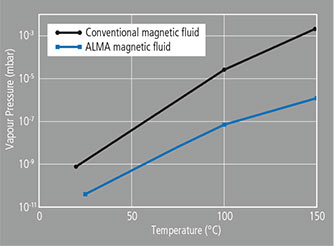

ALMA uses a special magnetic fluid that offers significant technical advantages compared to conventional fluids. Due to its significantly lower outgassing, this fluid excels above all in applications involving thermal loading. The table shows the change in vapor pressure with increasing temperature (the lower the vapor pressure, the lower the outgassing of the fluid). Depending on the application parameters, the vacuum quality thus improves significantly when the ALMA fluid is used. The magnetic fluid in our rotary feedthroughs is hydrocarbon-based and contains an oil that exhibits the lowest vapor pressure of all currently known hydrocarbon oils. The vapor pressure at room temperature is 4 x 10-11 mbar and increases to only 7 x 10-8 mbar at 100 °C. At present this fluid is used exclusively by ALMA.

The table shows the change in vapor pressure with increasing temperature (the lower the vapor pressure, the lower the outgassing of the fluid). Depending on the application parameters, the vacuum quality thus improves significantly when the ALMA fluid is used. The magnetic fluid in our rotary feedthroughs is hydrocarbon-based and contains an oil that exhibits the lowest vapor pressure of all currently known hydrocarbon oils. The vapor pressure at room temperature is 4 x 10-11 mbar and increases to only 7 x 10-8 mbar at 100 °C. At present this fluid is used exclusively by ALMA. Besides the quality criteria, the pollution control of the vacuum, the ALMA fluid also offers economic advantages: The maintenance costs are lower, as the typical shorter maintenance cycles due to the outgassing of conventional fluids are no longer necessary.

The material-bonded connection for UHV applications

If it is necessary to work in an ultra-high vacuum, leakage rates become a problem (e.g. when wafer-coating). ALMA rotary feedthroughs for use in ultra-high vacuums are designed so that a static sealing point is not required, as material bonding is used rather than an elastomer O-ring.The innovative design concept of material-bonded connections

The pole piece is materially bonded with the housing. Unlike the use of O-rings, this design principle ensures that no permeability to the vacuum occurs. Additional advantage: The pole piece can be cooled directly. This facilitates the bake-out process.

The pole piece is materially bonded with the housing. Unlike the use of O-rings, this design principle ensures that no permeability to the vacuum occurs. Additional advantage: The pole piece can be cooled directly. This facilitates the bake-out process.Advantages of ALMA sealing technologies

- Material-bonded joining technology for UHV rotary feedthroughs

- Special ALMA magnetic fluid for greater vacuum integrity and efficiency

- No particle formation

- 100 % maintenance-free