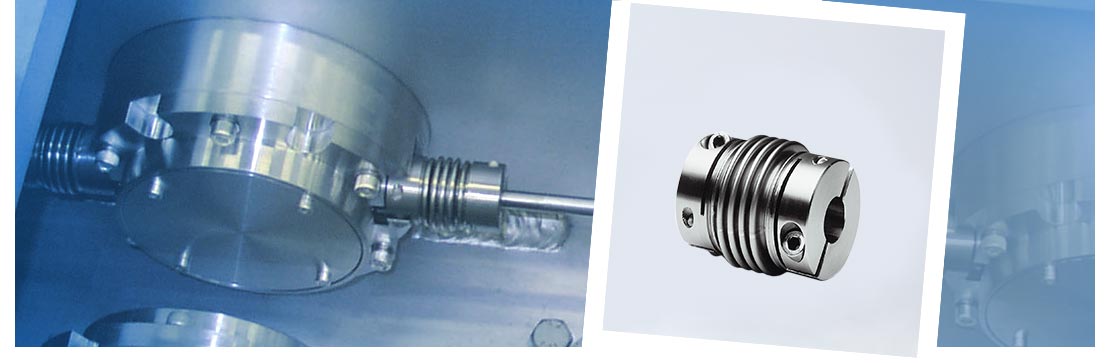

Torsion Stiff Metal Bellow Couplings

ALMA metal bellow couplings connect shafts absolutely torsion stiff, by balancing their misalignment in lateral, angular and axial direction. In circumferential direction they operate like a rigid element, this way they can transfer drag torques absolutely torsion stiff.

High stability of welding connection

ALMA couplings of ATM and AEKN types are generally welded together at clamping hubs and metal bellow. Therefore the connection has a high resistance against acids or other aggressive media.

High stability of welding connection

ALMA couplings of ATM and AEKN types are generally welded together at clamping hubs and metal bellow. Therefore the connection has a high resistance against acids or other aggressive media.

Corrosion-free stainless steel version

ALMA couplings made of stainless steel are corrosion-free and therefore ideal for operating conditions with aggressive media and vacuum or clean room applications. Because of their high operating temperature rating of up to 300 °C they are ideal for high demands in chemical, food and vacuum applications.

ALMA couplings made of stainless steel are corrosion-free and therefore ideal for operating conditions with aggressive media and vacuum or clean room applications. Because of their high operating temperature rating of up to 300 °C they are ideal for high demands in chemical, food and vacuum applications.

Direct link to GETECNO, our distributor for Germany and Italy, who sells our metal bellow couplings under the brand RODOFLEX®. GETECNO offers you comprehensive storage services and quick deliveries.

Direct link GETECNO

Direct link GETECNO

Miniature Metal Bellow Couplings

The miniature couplings type AMK and AMKN balance misalignments of rotating shafts and ensure an absolute synchronized transfer of rotating movements. They feature a low angular momentum and high torsion stiffness. They are applicable for nominal torques of 0,25 Nm - 12 Nm for shaft diameters of 1 mm - 24 mm.

Benefits at a Glance

- Low angular momentum

- Balancing of misalignments

- Temperature range up to 80°C

- Compact Design

- Free of wear and play

- Easy Mounting and Demounting

Torsion stiff Metal Bellow Couplings

ALMA Metal Bellow Couplings type ATM feature a welded bonding. This ensures higher temperature resistance and higher mechanical strength. Clamping types are conical clamp connections, radial or axial clamping hubs, etc. ALMA Metal Bellow Couplings are applicable for nominal torques of 10 Nm - 320 Nm for shaft diameters of 8 mm - 60 mm.

Benefits at a Glance

- Low angular momentum

- High torsion stiffness

- Balancing of misalignments

- Temperature range up to 300°C

- Variable clamping possibilities

- Torque transfer exact and free of play

- Easy Mounting and Demounting

Torsion Stiff Metal Bellow Couplings Product Overview

| Type | Benefits | Clamping, connection hub-bellow | Material | Transferable torques and deliverable sizes | |

|---|---|---|---|---|---|

|

AMK | Miniature type for low torques | Radial threaded pin, adhesive bonding | Hubs: AlMgSi1 Bellows: CuZn20 |

0,25-12,0 Nm D1/D2 1-24 mm |

|

AMKN | Miniature type for low torques | Radial clamping hubs, adhesive bonding | Hubs:AlMgSi1, Bellows: CuZn20 |

0,4-12,0 Nm D1/D2 3-20 mm |

|

AEKN | Miniature type for applications in vacuum or aggressive media | Radial clamping hubs, weldment | Hubs: 1.4305, Bellows: 1.4571 |

1,8-10,0 Nm D1/D2 3-14 mm |

|

ATMK | For applications in vacuum or aggressive media, for high torques | Hubs: radial weldment | Hubs: 1.4305, Bellows: 1.4571 |

10,0-320,0 Nm D1/D2 8-60 mm |

|

ATMN | For high torques and axial clamping | Conical clamp connection, axial clamping, weldment | Hubs: 1.4305, Bellows: 1.4571, Socket: 42CrMoS4 |

10,0-320,0 Nm D1/D2 8-41 mm |

|

ATMF | For applications in vacuum or aggressive media, for high torques and axial clamping | Axial clamping, fitting flange | Hubs: 1.4305, Bellows: 1.4571 |

10,0 - 320,0 Nm D1/D2 25-50 mm |

|

ATMB | For applications in vacuum or aggressive media, for high torques | Radial clamping, Fit-in-key | Hubs: 1.4305, Bellows: 1.4571 |

20,0 - 320,0 Nm D1/D2 10-42 mm |

|

AKS | Rigid type | Radial clamping, threaded pin | AlCuMgPb | D1/D2 2-12 mm |