Securable Shaft Nuts for Radial Clamping

The Pros at a Glance

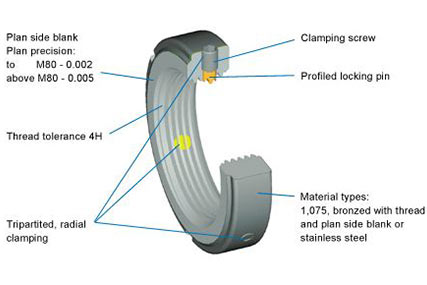

Tripartite Clamping

ALMA shaft nuts for radial clamping are basically fabricated with a three part clamping. In this system, 30 % higher clamping force of the installation can be reached as compared to dual clamping.

Better Inherent Stability

The radial construction dimension of the shaft nuts has a higher cross-section and therefore provides a better inherent stability.

Higher Axial Forces

Some types are fabricated as a broad version, so that high axial forces can be transferred.

High Planar Precision Running

The shaft nut thread and the planar side are fabricated in one clamping so a high planar precision run can be achieved.

ALMA shaft nuts for radial clamping are basically fabricated with a three part clamping. In this system, 30 % higher clamping force of the installation can be reached as compared to dual clamping.

Better Inherent Stability

The radial construction dimension of the shaft nuts has a higher cross-section and therefore provides a better inherent stability.

Higher Axial Forces

Some types are fabricated as a broad version, so that high axial forces can be transferred.

High Planar Precision Running

The shaft nut thread and the planar side are fabricated in one clamping so a high planar precision run can be achieved.

Clamping Screws

With the integrated clamping screws and locking pins, there is no more need to use locking plates to fix the shaft nut. The locking pins are fabricated together with the shaft nut thread, so that the planar catch is not altered during clamping.

No more Self-effort

No more nut is necessary to fix the locking plate, so that you don't need to go through any expensive milling process. Also additional deburring of the bolt thread is no longer necessary.

With the integrated clamping screws and locking pins, there is no more need to use locking plates to fix the shaft nut. The locking pins are fabricated together with the shaft nut thread, so that the planar catch is not altered during clamping.

No more Self-effort

No more nut is necessary to fix the locking plate, so that you don't need to go through any expensive milling process. Also additional deburring of the bolt thread is no longer necessary.

This type of shaft nut is fixed radially by clamping screws on the shaft. It is perfectly usable as a lock nut as it locks against dismantling independent from the locked torque of the shaft nut.