Screws for Vacuum Applications

The challenge of thin air.

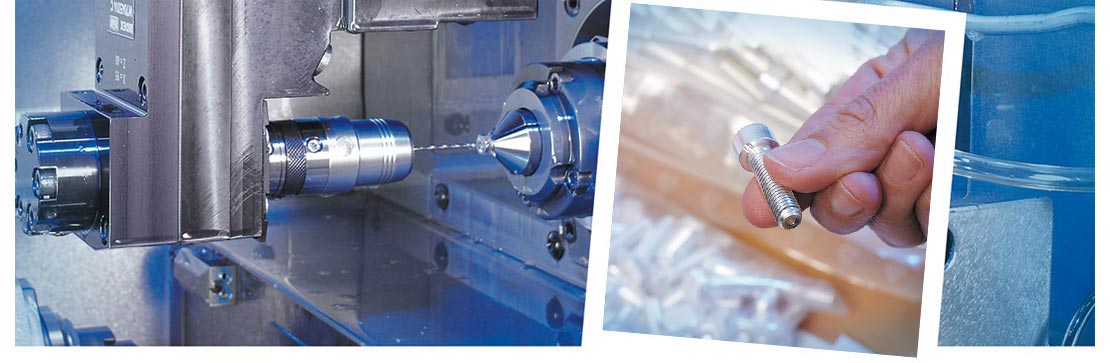

ALMA driving elements finishes ordinary screws by subjecting their surfaces to high-grade precision machining and modifying their “aerodynamics”. With the perfection of their properties, they become very special ALMA vacuum screws.

With ALMA vacuum screws, the joints in your vacuum assemblies can be quickly and very conveniently vented – in their entirety. Holes to vent the entire vicinity of the screw are no longer required, thus reducing your workload and safeguarding the vacuum.

Each silver-plated screw is a real masterpiece.

The vacuum screws look precious, showing that they have been finished for a special purpose.With ALMA vacuum screws, the joints in your vacuum assemblies can be quickly and very conveniently vented – in their entirety. Holes to vent the entire vicinity of the screw are no longer required, thus reducing your workload and safeguarding the vacuum.

The four main production steps in the finishing of a vacuum screw

1. High-precision drilling

What makes ALMA vacuum screws special is, firstly, that they have a highly accurate, continuous vent hole. The ALMA screw is drilled over its entire length in a single direction, thus totally excluding the risk of hole offset and of burrs in the screw’s interior.

2. Milled countersink

Secondly, ALMA vacuum screws have a countersink milled under the head as standard. This ensures reliable thread venting, so there is no longer any need for a spring washer or holes drilled in the joint assembly.As a consequence, many of the problems associated with vacuums are solved right at the start of the development phase.

3. Superfine post-rolling

The phenomenon of cold welding is a familiar problem of stainless steel screws.The threads of ALMA vacuum screws are fully post-rolled and are thus finished with absolute dimensional and shape accuracy. The fine post-rolling of the threads compresses the flanks and increases surface strength. Without post-rolling there is an elevated risk of thread damage, which is ultimately the cause of cold welding.

The use of thread inserts can also be dispensed with thanks to the high dimensional and shape accuracy of the rolled thread. Reliable re-use of ALMA vacuum screws is therefore also ensured.

4. Silver- and gold-plating

ALMA vacuum screws are fully silver-plated or also partially gold-plated.Thanks to this special surface finish, the thread displays extremely smooth action. In addition, silver has an extremely low outgassing rate that makes it ideal as a material for surface finishing. Absolutely perfect for a 100 per cent vacuum.

Each and every day

Joints in vacuum assemblies call for special attention, as these are often the weak points when complete assemblies have to be vented. Extended pump-down time or insufficient final pressure can often simulate a leak, although this may be purely virtual. This is because cavities in threaded joints that cannot be effectively vented give rise to “virtual” leaks. Further cross bores in the joint assembly are necessary to fully vent blind holes. Threads are usually vented with the aid of inserted spring washers. All this means time-consuming procedures and the input of extra material.With ALMA vacuum screws, all the joints in your vacuum assemblies are reliably, quickly, conveniently and fully vented. Your workload is minimal and the vacuum is given maximum protection.