Measurement and documentation

Quality assurance with high-precision coordinate testing services

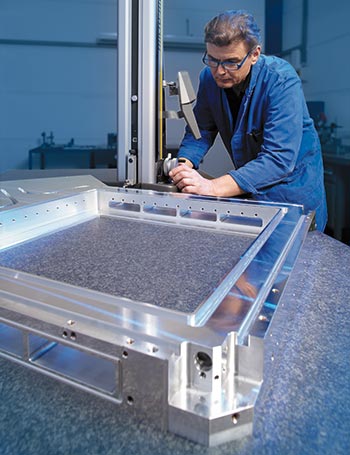

Air-conditioned precision measuring room

In our fully air-conditioned measuring room conforming to VDI/VDE 2627-3, we can measure components in an measuring range of up to W 2,000 x D 1,200 x H 1,000 mm and a weight of up to 2,000 kg with high precision on our advanced 3D coordinate measuring machine.In our CAM programming unit, new measuring programs are generated concurrently with the measuring process on the basis of machine simulation, inclusive of collision checks.

Our portal measuring machine permits the tactile scanning of straight lines, planes, circles, cylinders, cones, spheres and curves and ensures high measuring precision.

In order to achieve maximum measuring accuracy and reproducible values, the components are temporarily stored in the air-conditioned measuring room in a roughly 20 m² storage space until the measuring temperature is reached, at which point the required shape and position tolerances can be checked.

From leak testing to particle detection

To achieve the highest standards of precision, the components and assemblies we produce undergo painstaking quality control after individual production steps and during final inspection. It goes without saying that our measuring instruments and testing equipment are regularly calibrated for this.

Our customers benefit from these stringent tests by obtaining quality products that are guaranteed to meet the contractually agreed standards.

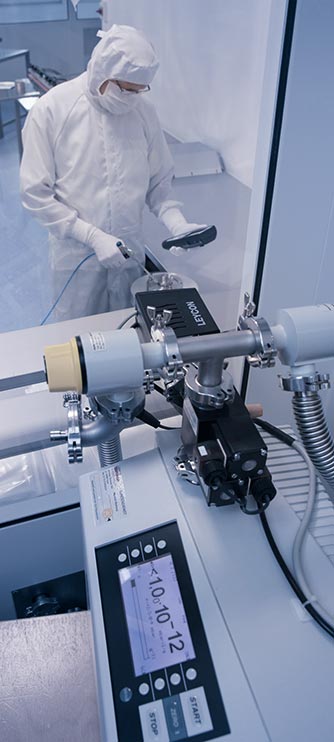

In our testing facilities with their advanced equipment, we check dimensional accuracy to within a few thousandths of a millimetre and, if necessary, carry out leak tests with our helium leak-testing facility with its detection sensitivity of <=1x10-9 mbar•l/s.

He leak tests of assemblies and end products can also be carried out in the cleanroom by intelligently arranging the leak test equipment starting in the grey room, so that contamination from the test set-up is reliably excluded.

Visual inspections for particle contamination can be performed with white or UV light as well as with a CleanoSpector or light microscope.

Visual inspections for particle contamination can be performed with white or UV light as well as with a CleanoSpector or light microscope.ALMA cleanroom testing equipment

- Visual inspection with white or UV light

- Light microscopic inspection

- Fluorescence meter

- Tensiometer

- Particle counter

- Wipe tests

- Water break tests

Quality audits to customer specification

We are constantly planning, consolidating and improving our product quality and enable our customers to carry out quality audits.Thanks to this cooperation between external quality professionals and our trained QM staff, ALMA regularly achieves outstanding ratings.